Reverse Osmosis

Reverse Osmosis Products

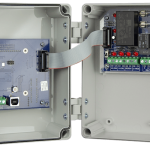

CHIP RO Controller

An amazing controller for small RO's.

Features:

- Powers up to 2HP Motors @ 240VAC (1HP @ 120VAC)

- Extensive Flush Options

- Fully Featured, runs the same software as our larger RO controllers

- Also available in a horizontal configuration.

- Available as a UL listed industrial control panel.

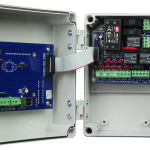

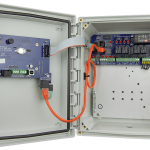

ROC-2HE RO Controller

A Full Featured Reverse Osmosis Controller for Small RO systems.

Features:

- Powers up to 2HP Motors @ 240VAC (1HP @ 120VAC)

- Permeate TDS, Feed TDS and % Rejection

- Extensive Flush Options

- Fully Programmable

- Low Cost Custom Graphics Available

- Available as a UL listed industrial control panel.

ROC-3HE RO Controller

Compact RO Controller for large Single Phase RO Systems.

Features:

- Powers up to 5HP Motors @ 240VAC

- Rugged 40A contactor for extended life

- Permeate TDS, Feed TDS and % Rejection

- Extensive Flush Options

- Fully Programmable

- Low Cost Custom Graphics Available

- Available as a UL listed industrial control panel.

ROC-5 RO Controller

Full featured RO controller for complex RO systems.

Features:

- Designed for 3 Phase motor control

- Modern UL 508E motor control system combines Disconnect, Circuit Breaker, Overload and motor control in a single coordinated system

- The ROC-5 is available as a UL 508a Industrial Control Panel.

- Permeate TDS, Feed TDS and % rejection

- Virtually unlimited system configurations available, multiple motors, control transformers, etc.

- Extensive Flush Options

- Fully Programmable

WMC-1 Watermaker RO Controller

The Rugged and Reliable Watermaker RO Controller.

Features:

- Advanced power supply allows operation on even the flakiest power sources

- Remote control option

- Freshwater Flush, Idle Flush

- Permeate TDS

- High Pressure shutdown

- Pump oil change interval alarm or shutdown

- Frill-free reliability, when pure water matters more than bells and whistles

RO side-by-side

| MegaTron MR | Series 150 | Series 100 | Series 75 | CHIP | ROC-2HE | ROC-3HE-20 | ROC-3HE-40 | ROC-3-10-MS12-3 | ROC-5-10-MS12-3 | ROC-5-12-MS22-3 | |

| Inputs | |||||||||||

| Feed pressure switch | |||||||||||

| Pretreat lockout | |||||||||||

| Tank switch(es) | |||||||||||

| High pressure switch | |||||||||||

| Feed conductivity (TDS) | |||||||||||

| Permeate conductivity (TDS) | |||||||||||

| FEED pH | |||||||||||

| Permeate pH | |||||||||||

| Feed ORP | |||||||||||

| Permeate ORP | |||||||||||

| Flow meters | |||||||||||

| 4-20mA pressure switch | |||||||||||

| 4-20mA inputs | Up to 16 | ||||||||||

| Outputs | |||||||||||

| Feed valve | |||||||||||

| Flush valve | |||||||||||

| Feed pump | |||||||||||

| Divert/Alarm | |||||||||||

| Motor contact type | DP | Relay | Relay | Relay | Relay | Relay | DP | DP | IEC | IEC | IEC |

| Motor HP/voltage | Every option | Every option | Every option | Every option | 1HP@120V / 2HP@240V | 1HP@120V / 2HP@240V | 3HP@240V | 5HP@240V | 3HP@208V / 7.5HP@460V | 3HP@208V / 7.5HP@460V | 10HP@208V / 15HP@460V |

| Communications | |||||||||||

| WebAdvantage | |||||||||||

| Dual communication cards | |||||||||||

| 40mA Outputs | Up to 16 | ||||||||||

| Enclosure (inches) | 12 x 10 x 6 | 8 x 6 x 4 | 8.25 x 5 x 3 | 7.6 x 4.6 x 2.2 | 7 x 5 x 2.5 | 7 x 7 x 4 | 7 x 7 x 4 | 7 x 7 x 4 | 10 x 8 x 6 | 10 x 8 x 6 | 12 x 10 x 6 |

Note: (stars) are for pressure switches sharing a single input.

Series 150 RO Microprocessor Controller

Features:

- Relay outputs on the Series 150 Controller operate the high pressure pump, inlet valve, flush valve, permeate divert valve, and remote alarm.

- The relay for the high pressure pump can operate a 1 horse power single phase pump motor directly without external motor controls.

- Incorporate controls for large hours power motors.

- Dry contact inputs control the start and stop of the RO unit by monitoring the inlet pressure, tank level, and pretreatment equipment.

- Permeate monitor and sensor are temperature compensated.

- RO high pressure pump motor

- Inlet solenoid valve

- Automatic flush solenoid valve

- Low feed pressure switch

- High pump pressure switch

- RO storage tank level switches (1 or 2)

- Permeate TDS/Conductivity

- Water temperature

- Pre-treatment lockout

- Operating hours

- Feed TDS/conductivity

- I/O Expander, permeate divert or remote alarm relay and auxiliary relay with tank-low input

- Power: 120/240 VAC -15+10%, 50/60 Hz, 25 Watts

- Enclosure: 8”x6”x4” NEMA 4X (The controller can be custom configured in larger enclosures to incorporate the controller and motor starters for larger 3 phase systems.)

- Inlet solenoid valve 120/240 VAC 5 amp maximum

- RO pump 120/240 VAC 1HP, single phase maximum

- Flush solenoid valve 120/240 VAC 5 amp maximum

Series 100 Light Commercial RO Controller

The Series 100 Controller is an ideal solution for the monitoring and control of light commercial reverse osmosis units. This economical controller provides relays for the RO pump, inlet solenoid valve, and membrane flush solenoid valve.

The dry contact switch inputs monitor storage tank level, low and high pressure switch signal, and system lockout for pretreatment backwash or regeneration for on/off operation. All inputs and outputs are controlled with time delays for proper operation.

Additionally, the TDS value incorporates a field adjustable set point for water quality threshold, allowing the unit to produce a system warning if the water quality threshold is exceeded. LED indicates water quality and operating status.

Features:

- Economical controls

- Visual status LED

- TDS monitor w/ sensor (range 0-1000 PPM)

- Three digit LED display

- Jumper selectable flush type

- Jumper selectable switch inputs

- TDS calibration adjustment

- TDS set point adjustment

- Quick disconnect high voltage terminals

- Plug in terminals for switch inputs

- Panel mountable enclosure

Specifications:

- Power: 120 VAC or 240 VAC – 15+10%, 50/60Hz

- Environment: -22F to 140F, 0-95%RH, Non-condensing

- Enclosure: 8.25”x5.0”x3.0” ABS plastic

Input/Output Switches:

- Low pressure switch

- RO storage tank full

- Pretreatment Lockout (all switch inputs are jump selectable NO or NC)

Control Relays:

- Inlet solenoid valve 120/240 VAC 5 amp maximum

- RO pump 120/240 VAC 1HP, single phase maximum

- Flush solenoid valve 120/240 VAC 5 amp maximum

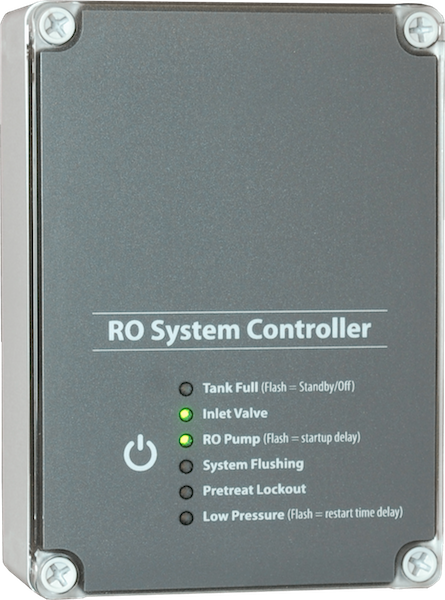

Series 75 RO Controller

The Series 75 Controller is designed for the small commercial Reverse Osmosis system. This controller incorporates relay outputs and dry contact inputs to either run or shutdown as necessary for proper operation. The Series 75 Controller has up to three relay outputs: inlet solenoid valve, RO pump motor, and an optional flush solenoid valve.

The controller’s three inputs will monitor the inlet pressure, tank level, and pretreatment lock. An LED on the front of the controller will visually indicate the operating status of the RO unit. The Series 75 controller can operate a one horse power single phase pump motor directly with the RO pump relay output. This controller provides crucial time delays required to prevent the RO unit from false shutdowns.

All of the adjustments are made with the six position dip switch located in the center of the PC board. This controller provides the OEM a sufficient level of control at an economical price.

Features:

- RO pump monitor

- Inlet solenoid

- Low feed pressure

- RO storage tank full pump

- Pre-treat lockout

Standard Time Delays:

- Tank Full/Pump OFF: 5 seconds

- Tank Full/Pump ON: 2 seconds or 15 minutes

- Pressure Fault: 2 seconds

- Pretreat Lockout: 2 seconds

- Automatic Reset: 60 minutes

- Pressure Fault Retry: 30 seconds, 5 minutes, 30 minutes

- Optional Auto Flush: 5 minutes

RA-6 Six Channel Remote Alarm

The RA-6 Remote Alarm unit is designed to communicate an alarm or abnormal condition of operating equipment to areas outside the equipment area. The unit is comprised of a base unit and a remote unit. The unit has 6 input channels and each channel can be individually configured in the base unit to monitor different types of input signals, such as dry contact, AC/DC voltage or open collector transistor. These signals can be from virtually any source such as conductivity/resistivity monitors, level switches, pressure switches, limit switches, motor contactors, etc.

The base unit provides power for the remote unit and has jumpers for configuring the input channels. Channels 1-4 have a fixed 1-second delay and channels 5-6 have either a fixed 1-second delay or an adjustable time delay. The remote unit has a green power on LED, a red alarm LED and red individual alarm LED’s. An audible alarm is provided with an alarm silence switch. The alarm silence can be maintained or timed. A power failure alarm is incorporated into the remote unit and also an optional alarm relay output.

Specifications:

- 120VAC, optional 240VAC 50/60Hz @ 2.4Watts

- Remote Unit: Nonmetallic, 4.6” x 4.6” x 2.25”

- Base Unit: NEMA 4X, 8” x 6” x 4”

- Dry contact, transistor closure, 12-120VAC/DC

- Unit will accept and process up to 6 individual alarm signals in any combination

- 8 Conductor, 20 gauge, up to 1000’

- Green power LED, red alarm LED’s

- 80 dB @ 3200Hz

- Optional Relay Output: SPDT 5A @ 120VAC